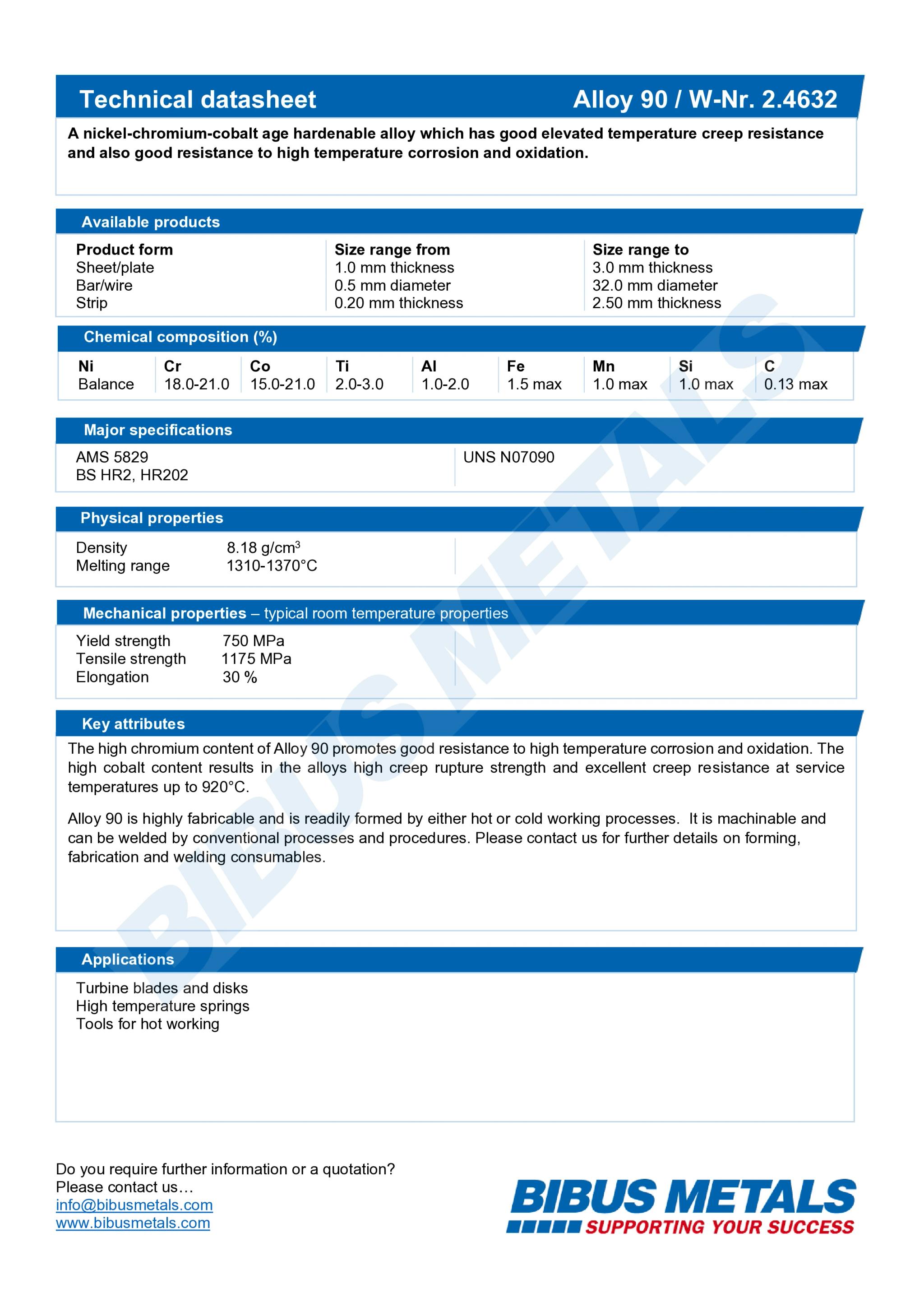

NIMONIC® Alloy 90

A precipitation-hardenable nickel-chromium-cobalt alloy having high stress-rupture strength and creep resistance at temperatures to about 1700°F (920°C). The alloy also has good resistance to high-temperature corrosion and oxidation. Used for blades and discs in gas turbines, hot-working tools, and springs.

Contact us if you have any questions.

Contact to BIBUS METALS SwitzerlandCold drawn, spring hard

Stock program

- 0.50 mm

- 0.60 mm

- 0.70 mm

- 0.80 mm

- 0.90 mm

- 1.00 mm

- 1.20 mm

- 1.25 mm

- 1.30 mm

- 1.50 mm

- 1.60 mm

- 1.80 mm

- 2.00 mm

- 2.50 mm

- 3.00 mm

- 3.50 mm

- 4.00 mm

- 4.50 mm

- 4.75 mm

- 5.00 mm

- 8.00 mm

- 9.00 mm

Details at a glance

Chemical composition

Ni

Balance

Cr

18.00 - 21.00 %

Co

15.00 - 21.00 %

Ti

2.00 - 3.00 %

Al

1.00 - 2.00 %

Fe

max. 1.50 %

Mn

max. 1.00 %

Si

max. 1.00 %

Cu

max. 0.20 %

Zr

max. 0.15 %

C

max. 0.13 %

B

max. 0.02 %

S

max. 0.015 %

Density

g/cm³

8.18

lb/in³

0.296

® trademarks of the Special Metals Corporation group of companies

.