The BIBUS METALS Group has a professional fleet of machinery at several locations, allowing us to optimally serve customer needs. In addition to cutting to size, we also offer beveling, pointing, stamping, and marking services (in collaboration with our subsidiaries), fully tailored to your specific requirements.

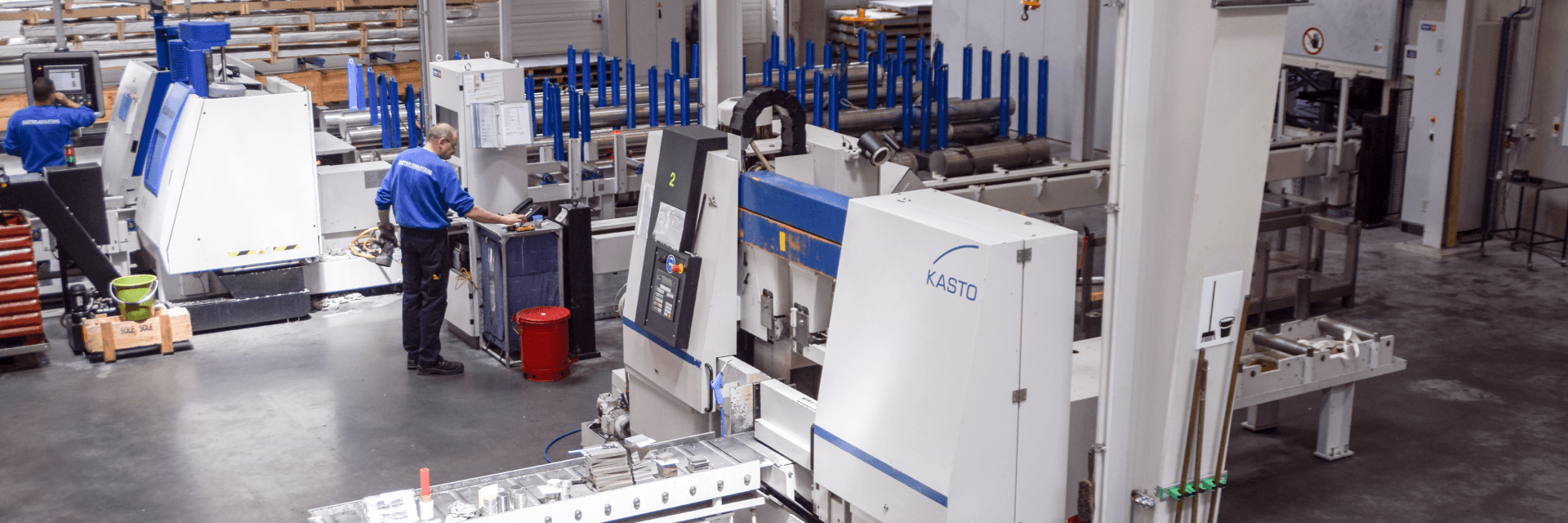

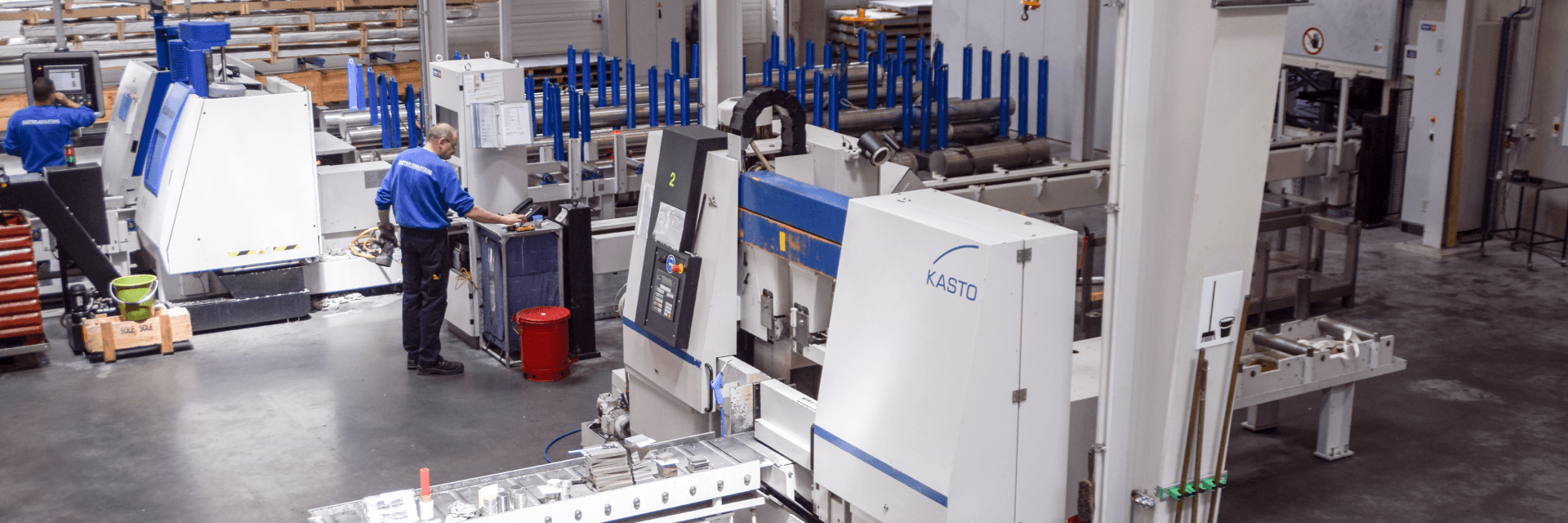

At our Swiss Service Center, 9 advanced circular saws and band saw machines ensure precision cutting, even for diameters up to 350 mm. This allows for the accurate and reliable processing of special materials and titanium alloys. Since its founding in 1979, BIBUS METALS AG has accumulated over 40 years of experience in cutting high-quality materials, guaranteeing outstanding expertise and quality.

The BIBUS METALS Group has extensive machining facilities that provide fast and precise processing for our customers. For the machining of special materials and titanium alloys, we use specially developed sheet and plate cutting machines, capable of handling sheet thicknesses up to 12 mm.

Our group boasts one of Europe's largest fully automated plate cutters. The Behringer LPS 25-125-6A machine enables the precise cutting of titanium sheets in sizes up to 2000 x 6000 mm and thicknesses up to 150 mm, meeting the highest customer requirements.

Waterjet cutting is performed using our own machines, as well as in collaboration with experienced partner companies, ensuring accurate and reliable results.

Micro water jet cutting

The micro water jet enables a refined process to be carried out in precision cutting. This high-precision technology reduces the jet diameter by a factor of 5 and makes water jet cutting more precise by a factor of 10. The micro water jet achieves a cutting accuracy of +/- 0.01 mm and a positioning accuracy of ±0.005 mm. The proven advantages of the cold cutting process remain unchanged.

In the pure water process, the cutting width was reduced to 0.2 mm in the abrasive process for hard materials such as nickel-based alloys and titanium. The new technology controls the cutting process and manipulates the cutting path depending on the contour and speed enabling a highly precise cut.

Standard waterjet cutting

Water jet cutting is highly efficient and at the same time less severe than other cutting techniques. Low process forces and thermal loads prevent bending or melting. We can cut filigree delicate contours from practically all nickel alloys and titanium alloys. Using our standard process we can cut a range of shapes and dimensions according to customer requirements and drawings and achieve tolerances of +/- 0.1 mm or +/- 0.2 mm.

We offer labelling options for flat and long products. On request with your order and/or article number. For long products also with hard stamping or needle embossing.

BIBUS METALS has an extensive and well-equipped warehouse network in Switzerland (Möhlin), Germany, Poland, the Czech Republic, Hungary, and China, ensuring fast and efficient product supply.

Our offices and warehouses are staffed with experienced professionals, manufacturing technicians, and metalworkers who have been working in the industry for many years. This expertise ensures the high level of knowledge and reliability that our customers can always count on.

We offer a wide range of cutting services, including sawing, as well as plasma and laser cutting, waterjet cutting, heat treatment, custom product manufacturing, and bespoke forging through our international network. We also provide delivery services, ensuring maximum convenience and flexibility for our customers.

For all the materials listed, we provide elbows, reducers, T-fittings, flanges, bushings, and other product forms, available upon request.

Insights