Alloy 626

2.4856 / UNS N06625 / N06626

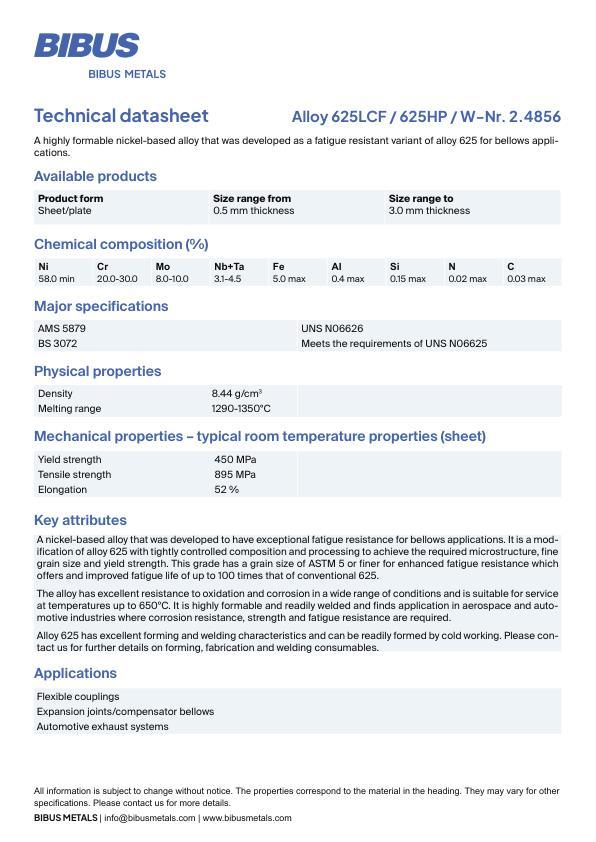

A nickel-chromium-molybdenum alloy that was developed to have excellent fatigue resistance especially for bellows applications. As with the widely known alloy 625 it has excellent resistance to oxidation and corrosion in a range of environments and conditions. Alloy 626 (Alloy 625 LCF) has a restricted composition and melting and processing of this alloy is closely controlled to provide a sheet product with optimum resistance to low-cycle and thermal fatigue at temperatures up to 650°C (1200°F). It finds application for flexible coupling bellows in both the automotive and aerospace sectors and expansion joints in various types of process piping.

Contact us if you have any questions.

Contact BIBUS METALS GmbH- 0.5 mm

- 0.6 mm

- 0.7 mm

- 0.8 mm

- 0.9 mm

- 1.0 mm

- 1.2 mm

- 1.5 mm

- 1.6 mm

- 2.0 mm

Details at a glance

Chemical analysis

Ni

min. 58.00 %

Cr

20.00 - 23.00 %

Mo

8.00 - 10.00 %

Nb¹

3.15 - 4.15 %

Fe

max. 5.00 %

C

max. 0.03 %

Mn

max. 0.50 %

Si

max. 0.15 %

S

max. 0.015 %

Al

max. 0.40 %

Ti

max. 0.40 %

P

max. 0.015 %

Co

max. 1.0 %

N

max. 0.02 %

¹ Plus Ta

Density

g/cm³

8.44

lb/in³

0.305

Recommended welding additive

Electrodes

INCO WELD 686CPT

Wire

INCO WELD 686CPT

® registered trademark of the Special Metals Corporation Group

.

Downloads

Data sheet Nickel Alloy 625 LCF

Data sheet Nickel Alloy 625 LCFContact us

Inge Schmelz-KleinmaxDigital Sales

English, German, French, Italian