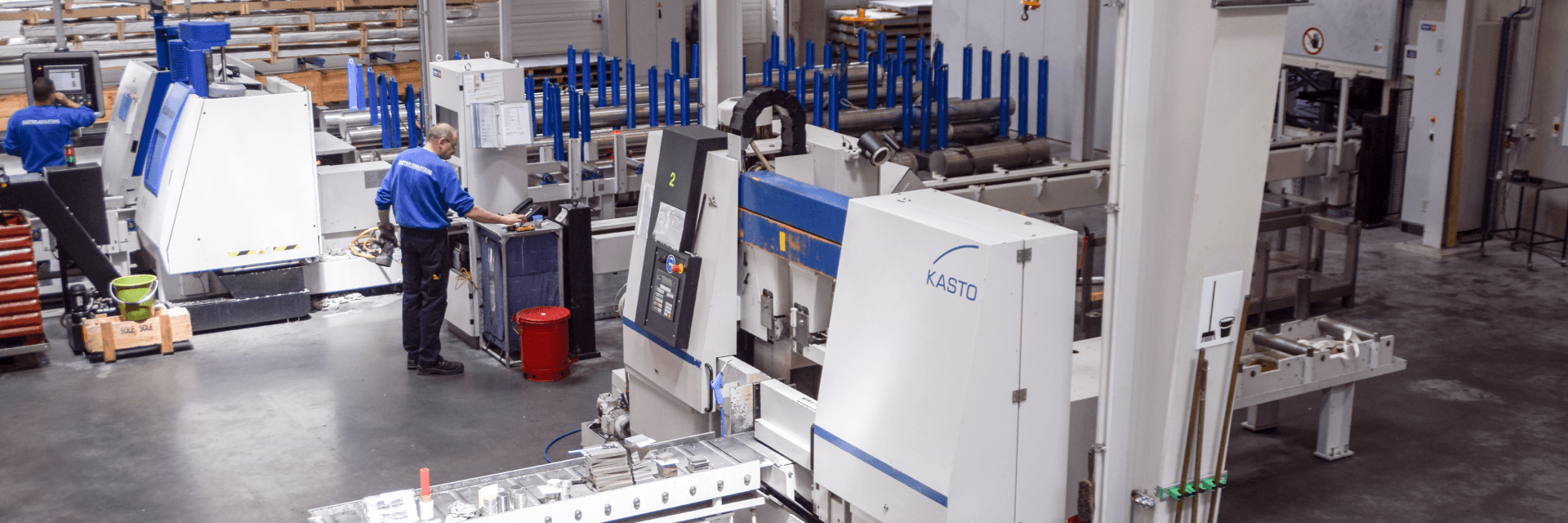

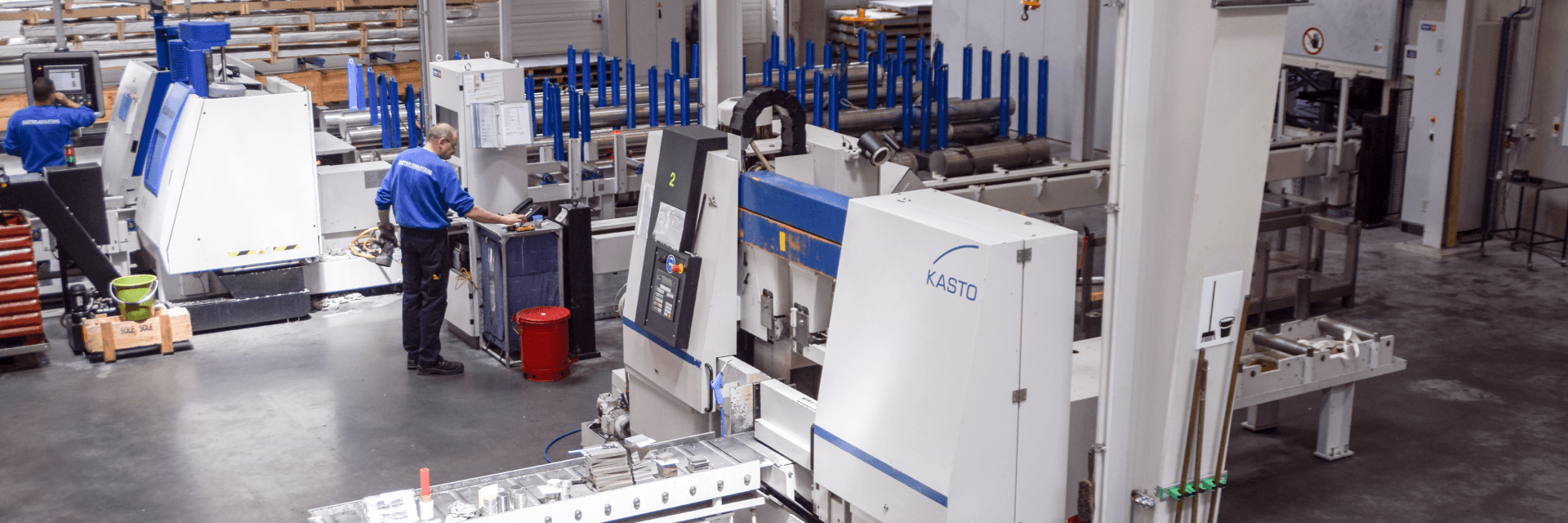

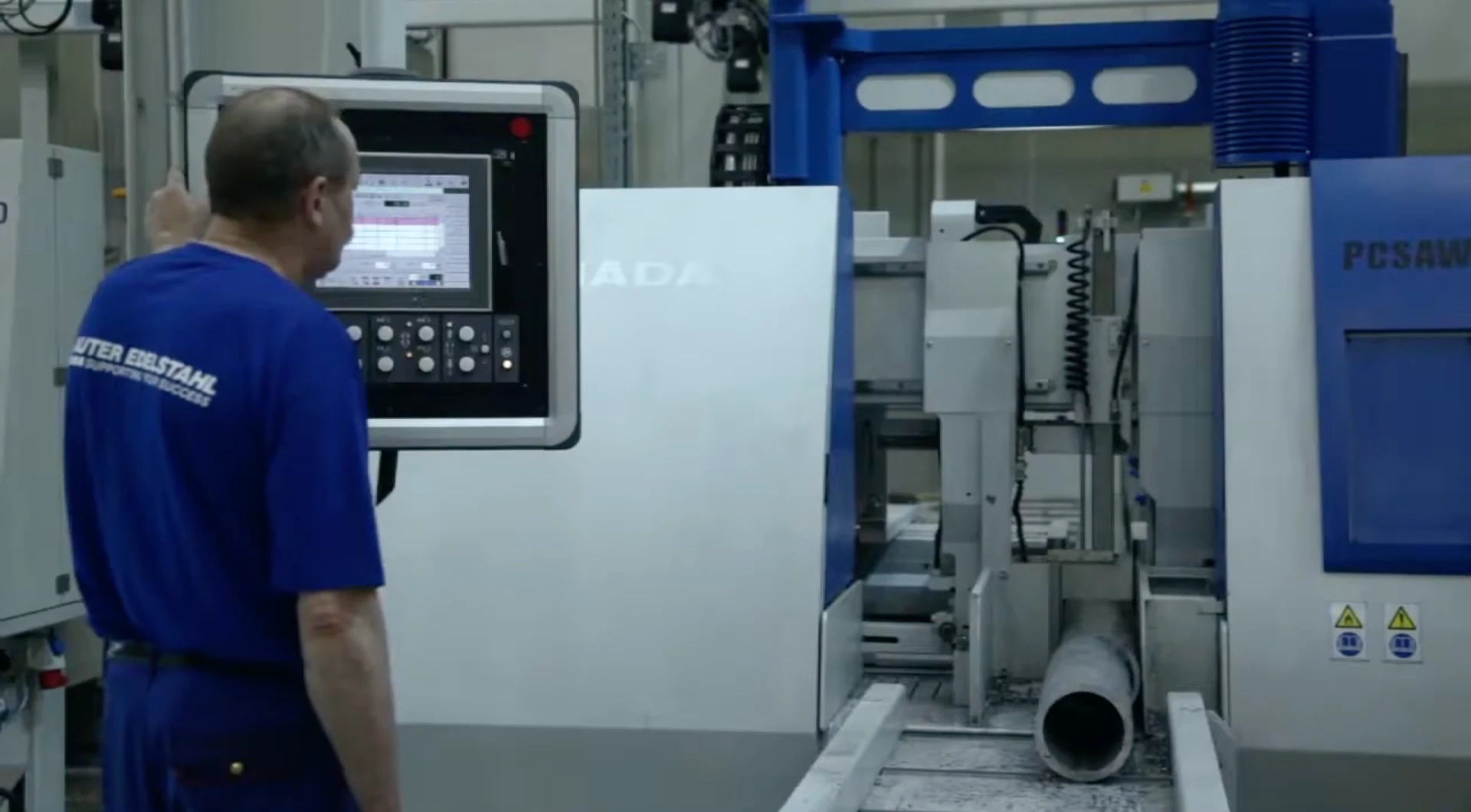

The BIBUS METALS Group has machinery at several locations in order to optimally realise professional processing and customer requirements.

For the cutting of high-performance materials and titanium alloys, the Service Center Switzerland has 9 powerful circular and band saw machines for precise cuts up to a diameter of 350 mm. BIBUS METALS AG has had experience in cutting special grades since the company was founded in 1979.

The BIBUS METALS Group has machining facilities at several locations in order to implement professional processing of customer requirements. We use specialist sheet/plate shears for high-performance materials and titanium alloys up to a sheet thickness of 12 mm. In addition, the group has one of the largest fully automatic plate saws in Europe. The Behringer type LPS 25-125-6A saw can cut titanium plates up to a size of 2000 x 6000 mm and a thickness of 150 mm according to the customer's requirements. Waterjet cutting is carried out with our own machines or in cooperation with selected partner companies.

Micro water jet cutting: The micro water jet enables a refined process to be carried out in precision cutting. This high-precision technology reduces the jet diameter by a factor of 5 and makes water jet cutting more precise by a factor of 10. The micro water jet achieves a cutting accuracy of +/- 0.01 mm and a positioning accuracy of ±0.005 mm. The proven advantages of the cold cutting process remain unchanged.

In the pure water process, the cutting width was reduced to 0.2 mm in the abrasive process for hard materials such as nickel-based alloys and titanium. The new technology controls the cutting process and manipulates the cutting path depending on the contour and speed enabling a highly precise cut.

Standard waterjet cutting: Water jet cutting is highly efficient and at the same time less severe than other cutting techniques. Low process forces and thermal loads prevent bending or melting. We can cut filigree delicate contours from practically all nickel alloys and titanium alloys. Using our standard process we can cut a range of shapes and dimensions according to customer requirements and drawings and achieve tolerances of +/- 0.1 mm or +/- 0.2 mm.

We offer labelling options for flat and long products. On request with your order and/or article number. For long products also with hard stamping or needle embossing.

We have well-stocked warehouses in Switzerland (Möhlin), Germany, Poland, the Czech Republic, Hungary and China.

Our office and field service with experienced specialists as well as factory technicians and metalworkers have many years of expertise.

We offer cutting services, shearing, sawing, burning (plasma/laser), water jet cutting, heat treatment, customised products and free-form forgings - all including delivery.

For all materials from our list: Elbows, reducers, T-pieces, flanges, flares and more.