INCOLOY® Alloy 800 H / HT

1.4876 / 1.4958 / 1.4959 / UNS N08810 / UNS N08811

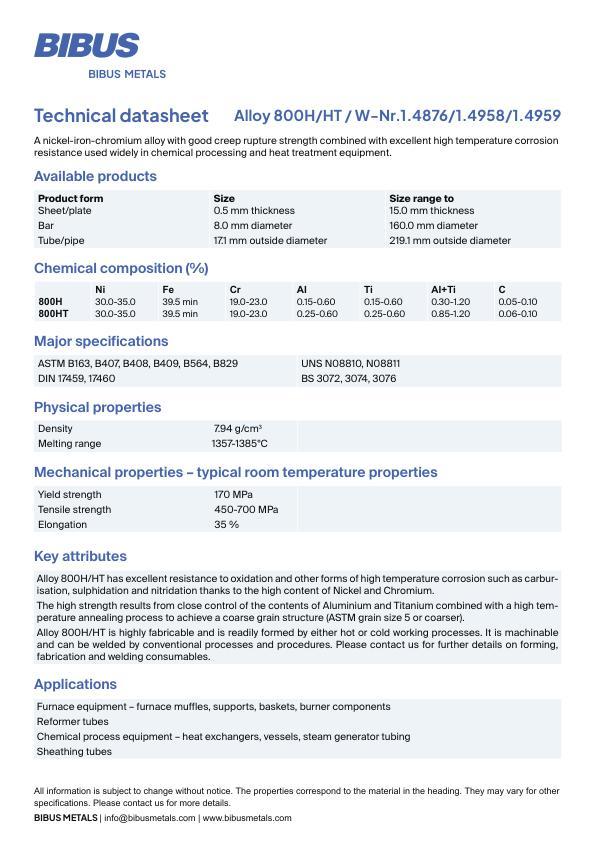

Nickel-iron-chromium alloys having the same basic composition as INCOLOY alloy 800 but with significantly higher creep-rupture strength. The higher strength results from close control of the carbon, aluminum, and titanium contents in con-junction with a high-temperature anneal. Used in chemical and petrochemical processing, in power plants for super-heater and reheater tubing, in industrial furnaces, and for heattreating equipment.

Contact us if you have any questions.

Contact BIBUS METALS SwitzerlandStock program

- 8.0 mm

- 9.0 mm

- 10.0 mm

- 12.0 mm

- 15.0 mm

- 16.0 mm

- 20.0 mm

- 25.0 mm

- 30.0 mm

- 35.0 mm

- 40.0 mm

- 45.0 mm

- 50.0 mm

- 55.0 mm

- 60.0 mm

- 70.0 mm

- 80.0 mm

- 90.0 mm

- 100.0 mm

Details at a glance

Chemical composition (800H*)

Ni

30.00 - 35.00 %

Fe

min. 39.50 %

Cr

19.00 - 23.00 %

Al

0.15 - 0.60 %

Ti

0.15 - 0.60 %

Al + Ti

0.30 - 1.20 %

C

0.05 - 0.10 %

* By special agreement, this product can be supplied with Al + Ti Content 0.4 - 0.7%

Density

g/cm³

7.94

lb/in³

0.287

Recommended Welding Products

Electrode

INCONEL 718

Electrode

INCO WELD A

Filler Metal

INCONEL 82

Filler Metal

INCONEL 617

® trademark of the Special Metals Corporation group of companies

.

.

Downloads

Data sheet Nickel Alloy 800H/HT

Data sheet Nickel Alloy 800H/HT