NIMONIC® Alloy 263

2.4650 / UNS N07263

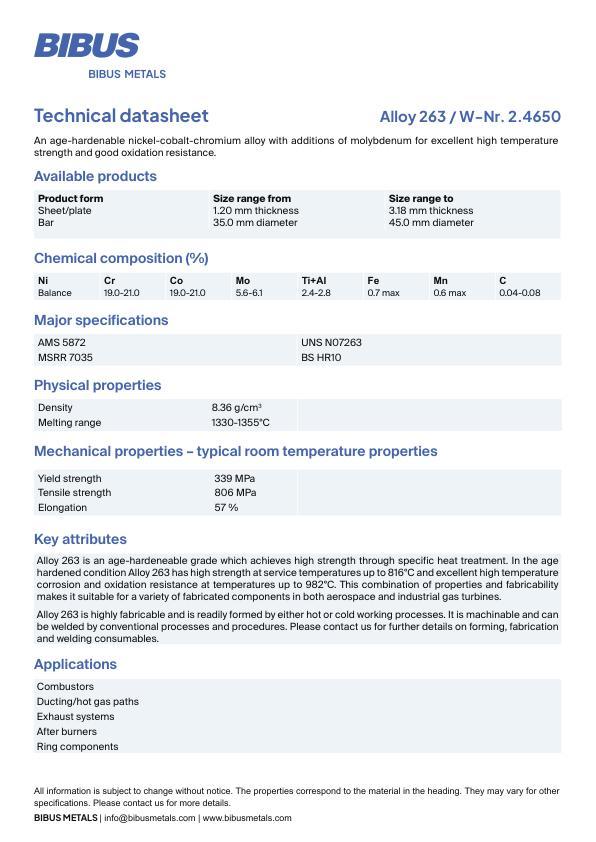

A nickel-cobalt-chromium alloy with additions of molybdenum which can achieve high strength through age-hardening. The alloy was designed specifically to combine good high temperature strength properties with excellent formability (in the annealed condition). It has high strength at temperatures up to 816°C and excellent oxidation resistance up to 982°C. The alloy is particularly suited to sheet fabrications and is used in both aircraft turbines and industrial gas turbines for rings, casings, low temperature combustors and transition liners.

Contact us if you have any questions.

Contact BIBUS METALS SwitzerlandStock program

- 1.20 mm

- 1.60 mm

- 3.17 mm

Details at a glance

Chemical composition

Ni

Balance

Cr

19.00 - 21.00 %

Co

19.00 - 21.00 %

Mo

5.60 - 6.10 %

Ti

1.90 - 2.40 %

Al

max. 0.60 %

Ti + Al

2.40 - 2.80 %

Fe

max. 0.70 %

Mn

max. 0.60 %

Si

max. 0.40 %

Cu

max. 0.20 %

S

max. 0.007 %

B

max. 0.005 %

Density

g/cm³

8.36

lb/in³

0.302

® trademark of the Special Metals Corporation group of companies

.

.

Downloads

Data sheet Nickel Alloy 263

Data sheet Nickel Alloy 263