INCONEL® Alloy 22

2.4602 / UNS N06022

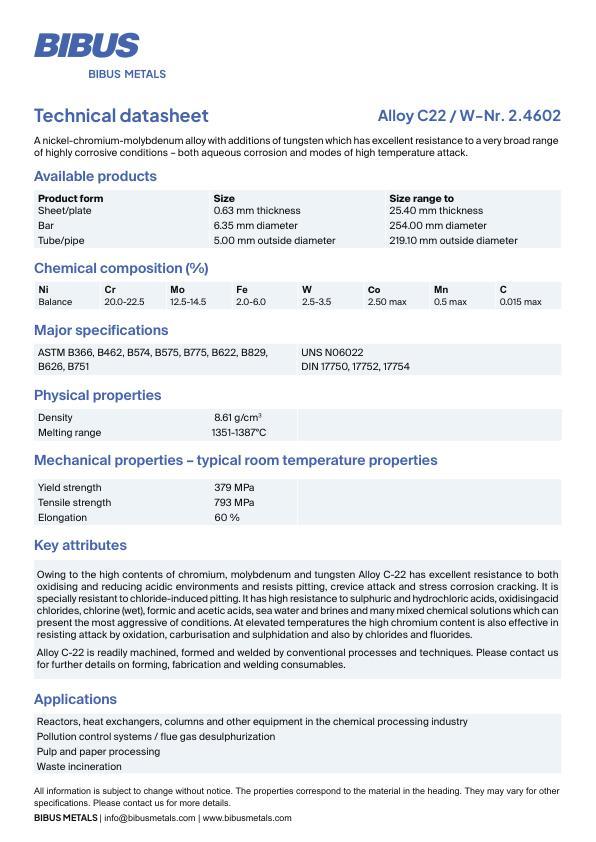

By virtue of its contents of chromium, molybdenum, and tungsten and controlled iron, this alloy exhibits excellent resistance to both oxidizing and reducing acid environments as well as those containing mixed acids. It is particularly useful for resistance to pitting and crevice corrosion in acid-halide environments. Applications include the chemical processing, pollution control, flue gas desulfurization, waste incineration, and pulp and paper processing industries.

Contact us if you have any questions.

Contact BIBUS METALS SwitzerlandStock program

- 6.35 mm

- 8.00 mm

- 9.52 mm

- 10.00 mm

- 12.70 mm

- 16.00 mm

- 20.00 mm

- 25.00 mm

- 25.40 mm

- 30.00 mm

- 31.75 mm

- 40.00 mm

- 44.45 mm

- 45.00 mm

- 50.00 mm

- 50.80 mm

- 57.15 mm

- 60.00 mm

- 63.50 mm

- 65.00 mm

- 70.00 mm

- 76.10 mm

- 80.00 mm

- 85.00 mm

- 90.00 mm

- 101.60 mm

- 115.00 mm

- 130.00 mm

- 139.70 mm

- 152.40 mm

- 165.10 mm

- 177.80 mm

- 203.20 mm

- 254.00 mm

Details at a glance

Chemical composition

Ni

Balance

Cr

20.00 - 22.50 %

Mo

12.50 - 14.50 %

Fe

2.00 - 6.00 %

W

2.50 - 3.50 %

Co

max. 2.50 %

Mn

max. 0.50 %

V

max. 0.35 %

Si

max. 0.08 %

P

max. 0.02 %

S

max. 0.02 %

C

max. 0.015 %

Density

g/cm³

8.61

lb/in³

0.311

Recommended Welding Products

Electrode

INCO WELD 686CPT

Filler Metal

INCO WELD 686CPT

® trademark of the Special Metals Corporation group of companies

.

.

Downloads

Data sheet Nickel Alloy 22

Data sheet Nickel Alloy 22